Showing all 4 results

-

$160.00

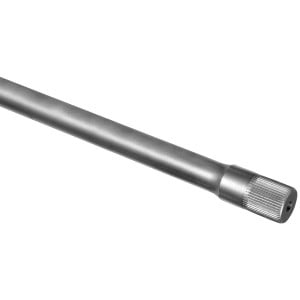

Gun-Drilled Torsion Bars for Micro Sprints

- Repeatable ride height without adjustment

- Holds rate for an extended period of time

- Unparalleled consistency, even after wrecks

- Seamless and smooth spline fit – leave your mallet at home

- Our manufacturing method differs from anything on the market

- Critical hardness and yield numbers are better than anything on the market

- Aircraft-quality chrome vanadium steel offers superior yield strength, fatigue properties, and impact toughness

- Vertical rack heat treating controls distortion

- CNC hobbed serration splines for precise and consistent fit

- Generous transition fillet radii essential to reduction of stress risers

- Lightweight gun-drilled design

- Additional attention directed to non-aggressive machining to impart a minimum amount of residual tensile stress

- Laser etched part number on torsion bar O.D.

-

$175.00

Gun-Drilled Torsion Bars for Sprint Cars

Strange Oval torsion bars have been winning races since 2008. We’re one of racings best kept secrets.

- Repeatable ride height without adjustment

- Holds rate for extended period of time – we’ve run them for 30+ races

- Unparalleled consistency, even after wrecks

- Seamless and smooth spline fit – leave your mallet at home

- Our manufacturing method differs from anything on the market

- Critical hardness and yield numbers are better than anything on the market

- Aircraft quality chrome vanadium steel offers superior yield strength, fatigue properties, and impact toughness

- Vertical rack heat treating controls distortion

- CNC hobbed serration splines for precise and consistent fit

- Generous transition fillet radii essential to reduction of stress risers

- Lightweight gun-drilled design

- Additional attention directed to non-aggressive machining to impart a minimum amount of residual tensile stress

- Shot peening provides increased torsional and bending fatigue life with the application of residual compressive stress

- Laser etched part number on torsion bar O.D. gives the relationship to a common solid bar’s equivalent rate

- Common solid bar number of equivalent rate also engraved onto the end of strange torsion bar for easy identification

-

$148.00

Solid Torsion Bars for NE Dirt Modifieds

Strange Oval torsion bars have been winning races since 2008. We’re one of racings best kept secrets.

-

- Available in solid bar equivalent rates of 900, 925, 950 in 29″ length

-

- Aircraft chrome vanadium steel offers superior yield strength, fatigue properties, and impact toughness

-

- Vertical rack heat-treating controls distortion

-

- CNC hobbed serration splines insures precise and consistent fit

-

- Additional attention directed to non-aggressive machining to impart a minimum amount of residual tensile stress

-

- Shot peening provides increased torsional and bending fatigue life with the application of residual compressive stress

Torsion Bars should be installed so that they always twist in the same direction. The bars retain a memory of the direction they are twisting, if they are twisted in the opposite direction the spring rate will be compromised and the bar could fracture. For this reason its always a good idea to mark the torsion bars to ensure they are used in the correct corner of the car.

-

-

$20.00

Torsion Bar Pre-Stressed Service

Re-stressing allows bars to have greater elastic twist angle and hence more wheel travel. It also drastically reduces bar settling eliminating a need for a racer to bounce a car up and down in order for it to settle at the correct height. During pre-stressing the bars are twisted within the plastic shear zone over a specific angle, unloaded and repeated two more times.

The Torsion bars’ strain curves are carefully monitored during the procedure. The procedure causes compressed residual stresses at the outer boundary of a bar increasing its yield strength. Ultimately, this saves time and, more importantly, conditions the bar for immediate on-track use in while also increasing the bars overall longevity.